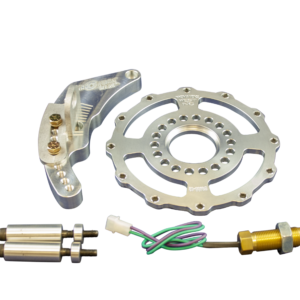

PSI Valve Springs – Dual Springs – CT33.01ML

Have any questions? Contact our team of experts.

*Please ensure you have double checked this part is right fit for your application. Still Unsure? Contact our team

PSI Valve Springs - Dual Springs - CT 33.01 ML

- SPRING O.D. 1.290"

- OUTER ID 0.966"

- INNER ID 0.716"

- SEAT PRESSURE 95 lbs @ 1.145"

- OPEN PRESSURE 305 lbs @ 0.715"

- RATE lbs/in. 488.0"

- MAX LIFT 0.430"

- COIL BIND 0.690"

1500 Series

This series has all the benefits of the 1200’s plus an additional nitriding operation. The nitriding process, which is also done in-house, increases the strength at the surface of the wire and at the same time causes a slight softening of the core material. This trade-off in hardness results in a gain in endurance for the Circle Track and Road Circuit teams who are limited by the onset of fatigue at the wire surface. Since Drag racers are not limited by endurance, the loss of core hardness does not make nitriding suitable for their applications.

Max Life Surface Preparation (ML)

A proprietary, multi-step surface enhancement process that has been proven to increase spring endurance, Max Life processing is available for any level of PSI spring and is very beneficial for those looking for increased endurance while maintaining their existing set-up.

PERFORMANCE SPRINGS INCORPORATED (PSI)

Co-founders, Bown and Luchi, started PSI in 1996 with the goal of making the best valve springs available for the racing industry. Prior to this time, all racing valve springs were made by big companies that focused largely on OEM valve spring applications. Their first year, PSI had only one customer – Randy Dorton, the legendary engine builder at Hendrick Motorsports.

WHAT STARTED IT ALL

Jeff Gordon got career win number 30 on February 22, 1998 at Rockingham, with a secret weapon: PSI valve springs. These were the first PSI valve springs used in a NASCAR race, but they wouldn’t be the last. Within a few years, virtually all of the teams were using PSI springs, revolutionizing engine building…as well as the country’s most popular motorsport.

ABOUT PSI SPRINGS

Each and every PSI spring begins with wire that is made from a variety of high quality Chrome-Silicon alloys. The catalog springs offered by PSI are made from commercially available alloys that use the latest developments in melt technology, composition control and casting practices, and these alloys are held to the strict cleanliness standards. As a result, the use of these super clean materials assures the lowest inclusion content commercially possible. For their custom spring applications, PSI offers the choice of a custom alloy that further improves on properties and cleanliness of the wire through the use of multiple vacuum arc remelting operations. Their superior technology does not stop with the wire. PSI uses state-of- the-art CNC equipment throughout the manufacturing process to ensure batch-to- batch consistency and valve springs that are held to the tightest tolerances in the industry. At PSI, all production processes are done in-house according to strict Quality Control procedures. All PSI springs are 100% load tested and set matched for the ultimate in customer convenience and satisfaction. Currently offering springs for circle track, drag and road racing, PSI springs also feature heat-treating, nitriding and the new Max Life surface preparation process for various applications.

At PSI, all production processes are done in-house according to strict Quality Control procedures, MADE IN USA

Through the use of the latest developments in melt technology, composition control and casting practices, our Chrome-Silicon alloys are held to the strictest cleanliness standards ever offered.

An industry leader since it was established in 1996, Performance Sprints has worked continuously to expand their range of specialized valve spring applications.

Additional information

| Weight | 3 kg |

|---|---|

| Dimensions | 39 × 10 × 9 cm |

You May Also Like...

OUR BRANDS

Discover the top-tier brands we partner with to provide you the highest quality race car parts and equipment. Each brand is carefully selected for its commitment to performance, reliability, and innovation.

Contact Us

If you’d like to find out more about our brands, products, or need expert recommendations, we’d love to hear from you. Give us a call or fill out the short form below. We’ll get back to you as soon as we can.